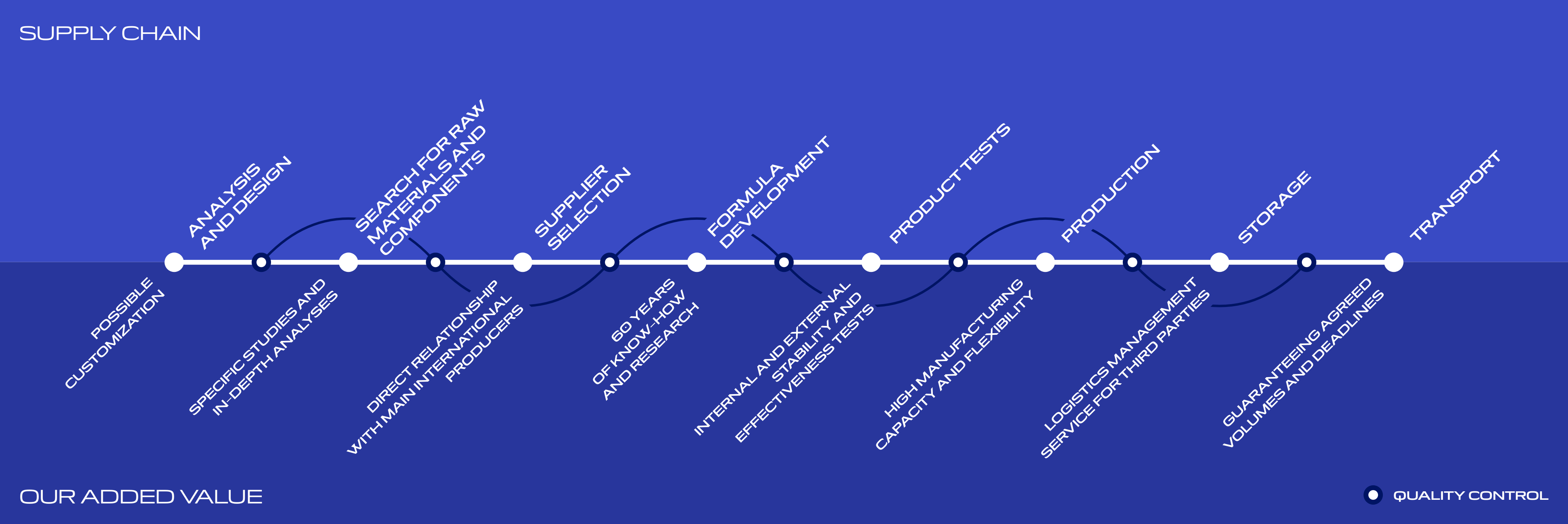

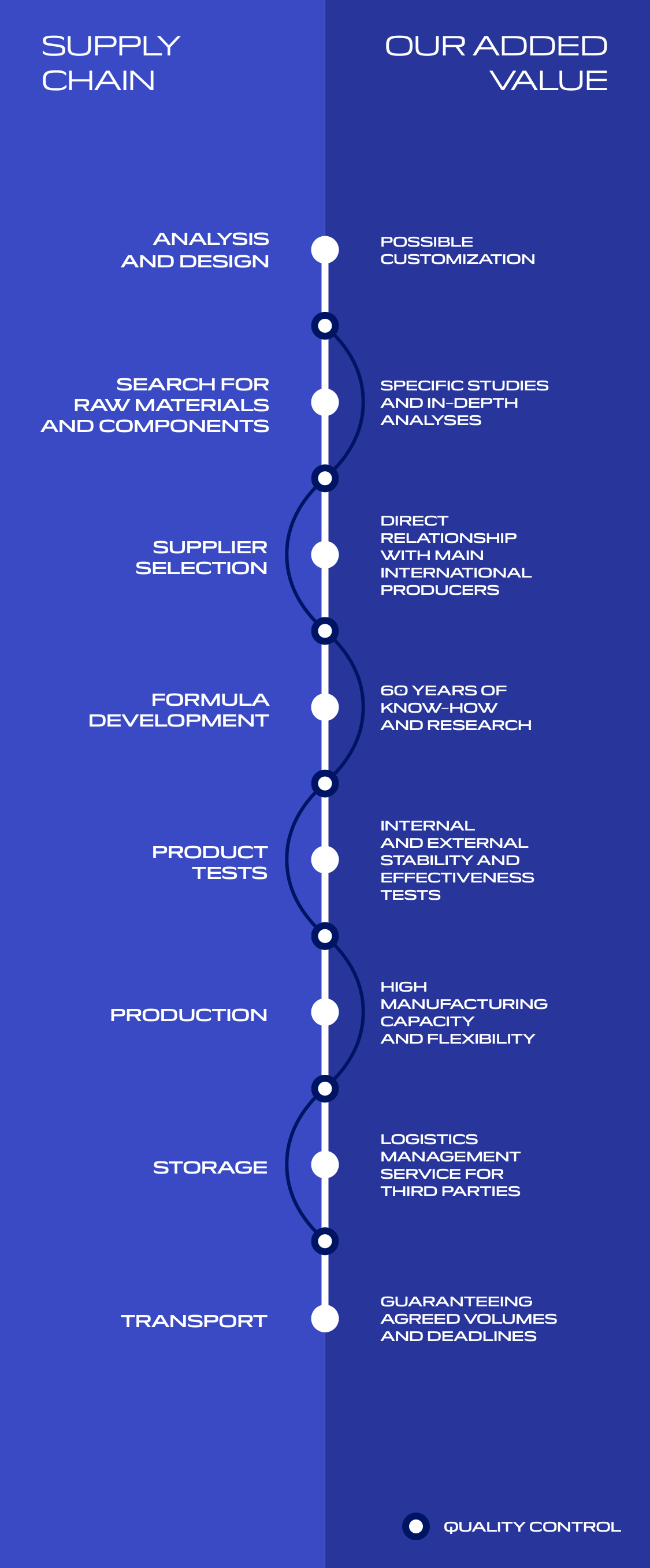

From analyzing your needs to a great result.

Every product we produce comes from our careful and constant listening to our clients' needs and from an in-depth analysis of the market.

We work with the client throughout the entire process of creating the product: concept and formulation, packaging and industrialization.

We share experiences and skills with the main players of the industry to innovate on raw materials and components.

We manage the entire production process directly: from the concept to the chemical formulation, from bottling to labelling. This way, we can guarantee top quality for our products, which is monitored throughout the chain.

Thanks to our lean supply chain, we can respond to every need quickly and flexibly.

The entire production process is carried out, checked, and managed inside MK's production plant, which covers an overall surface of 20,000 sqm. Our manufacturing capacity equals 45 million kg/year.

MK caters to every one of your needs. If you need a customized and unique product even in the packaging, you can count on us. Our Graphic & Print Department was conceived to help clients create and print made-to-measure labels that are customized both in content and graphic design.

A leading company in the market of professional cleaning products had set two important goals for itself: creating a premium line with its own brand and working with one single interlocutor to cover the entire cleaning market. The company was looking for a partner who could produce performing products, co-design, and offer a complete service at 360°. MK proved to be the right choice. The research and co-design allowed us to be engaged in every phase of the project, from the development of the formulas to the labelling of the entire range. The result was a top-level personalized range that could satisfy every specific need of the end user. Our client obtained the desired result: generating awareness and positioning themselves as a brand leader in their market of reference.

Methodology

Phase 1. Identifying needs. We analyzed the products in the category, the assortment, and formulas. We dedicated ourselves to a careful study of the end users’ needs as well as an analysis of the region of reference.

Phase 2. Creating a winning formula. We co-designed the formulas based on the established performance goals. At the same time, we dedicated ourselves to developing the pack, defining the specifications, and constructing an appropriate pricing.

Phase 3. Collaborating. We shared a production planning with the client. The company was able to count on post-sales assistance, both from the technical and commercial point of view and regarding aspects concerning the way of use and the products’ safety.

Benefits

- One single supplier for various services.

- Rationalization and optimization of the product range.

- Increased awareness and growth of market share.

The supply of the Sanigel hand sanitizer for sale and as a tool in sanitization protocols consolidated the relationship with one of our clients in the Do It Yourself channel. This client serves very diverse categories, both B2C and B2B. The quality of the product and service convinced the client to choose MK due to their need to insert a new category of professional cleaning product into the range: the Clean Professional line.

Methodology

Phase 1. Listening and Analysis. The client’s need was to seize a new business opportunity by integrating his offer with a new category of products for the H.A.C.C.P. protocol.

Phase 2. Create the winning formula. Thanks to our wide range of formulas, we were able to quickly identify a specific assortment and select the most suitable formulas for market needs. MK thus created a complete and highly effective range. The first results obtained during the testing phase were very positive.

Phase 3. Co-design. The client collaborated with us and was supported in every phase of the production process: from the concept to the packaging, from the training of employees to communication, and all the way to the insertion of the products on the shelves.

Benefits

- Creating a new line with more than 40 references tailored to the target of reference.

- Complete response to every need in terms of cleaning and sanitation, with specific products for surfaces, equipments, and environments.

- Growth in revenues thanks to the acquisition of the new H.O.R.E.C.A. target.

In 2020, the difficult management of mass gatherings was putting the summer season at risk. One of the biggest beach cooperatives in Italy, a consortium that unites more than 150 facilities among beach facilities, bars, and restaurants that cover more than 7 km of coast, entrusted MK with the sanitization protocol and supply of products for hand sanitation, sanitation of surfaces and environments. The collaboration with MK saved the season and guaranteed maximum safety in all facilities, bars, and restaurants.

Methodology

Phase 1. Listening and analysis. We carefully analyzed the needs of beach establishments, bars, and restaurants to outline a suitable plan of solutions to fully satisfy the needs of the various parties involved.

Phase 2. Sanitization plan. Every aspect was studied in every detail to guarantee the safety of all guests: from hand sanitation to the sanitation of sunbeds, baths, and showers. With the client, we worked out a sanitization plan for all environments and assessed the most appropriate products for every surface that was potentially at risk of contamination.

Phase 3. Provide guarantees for a successful season. We communicated the operations we had carried out to sanitize all environments in a clear and direct way. All guests understood that the facility or establishment in question was concerned with their safety and was working in collaboration with MK, a leading brand in the field of professional cleaning, to reduce risks drastically.

Benefits

- Guaranteed safety for all guests in the 150 beach establishments (about 4 million people).

- Confidence in outlining a correct protocol for sanitization procedures.

- Guaranteeing timely supply of products throughout the season thanks to MK’s logistic planning.

A leading multinational company in the Laundry & Home Care industry commissioned MK to develop a project for the European market under a tolling agreement.

Methodology

Phase 1. Collaborating with the client. MK selected and chose the formats of the most suitable packs for the project with the partner company.

Phase 2. Feasibility. We performed stability tests for each mixture for select packagings.

Phase 3. Full Service. The client chose the MK advantage entrusting us with various production activities: storing raw materials, mixing, purchasing and storing components, industrial planning for filling and logistic delivery.

Benefits

- Simplifying the process by means of one single supplier who coordinates and manages all operations.

- Saving time on production and real-time solutions.

- Cost control throughout the entire chain.

“Olfactory” awareness creates an emotional connection with the brand values and its places of belonging. An important player in the luxury retail sector, who already had an olfactory logo, asked us to use the fragrance of the brand in the hand sanitizer available to clients in store. Our long experience and research in the field of olfactory marketing allowed us to carry out this project and satisfy all the client’s expectations.

Methodology

Phase 1. Study of the fragrance. Under the expert guidance of a “Master Perfumer”, we sampled the brand’s fragrance and worked to create an essence that would be consistent with the company’s olfactory logo.

Phase 2. Research. The research and development lab honed a system for professional cleaning and sanitization with the requested olfactory note.

Phase 3. Concept development. The client’s satisfaction with the obtained result led him to ask us to develop further products, in addition to the hand sanitizer: an air freshener, a hand soap, a multi-use sanitizer, a floor detergent, and an anti-limestone cleaner for the bathroom.

Benefits

- Creating cleaning and sanitizing products with a fragrance consistent with the brand’s olfactory logo.

- Increasing store traffic and extending customer’s stay in store: “nice smell, I’ll walk in and stay with pleasure”.

- Increasing the average ticket thanks to the olfactory stimulation and connected feeling of wellbeing.

Italiano

Italiano